PUSHING THE LIMITS:

TODD PROCTOR WANTS TO MAKE A SMALLER, LIGHTER, STRONGER SURFBOARD, AND HE’S USING NEW TECHNOLOGIES TO DO IT.

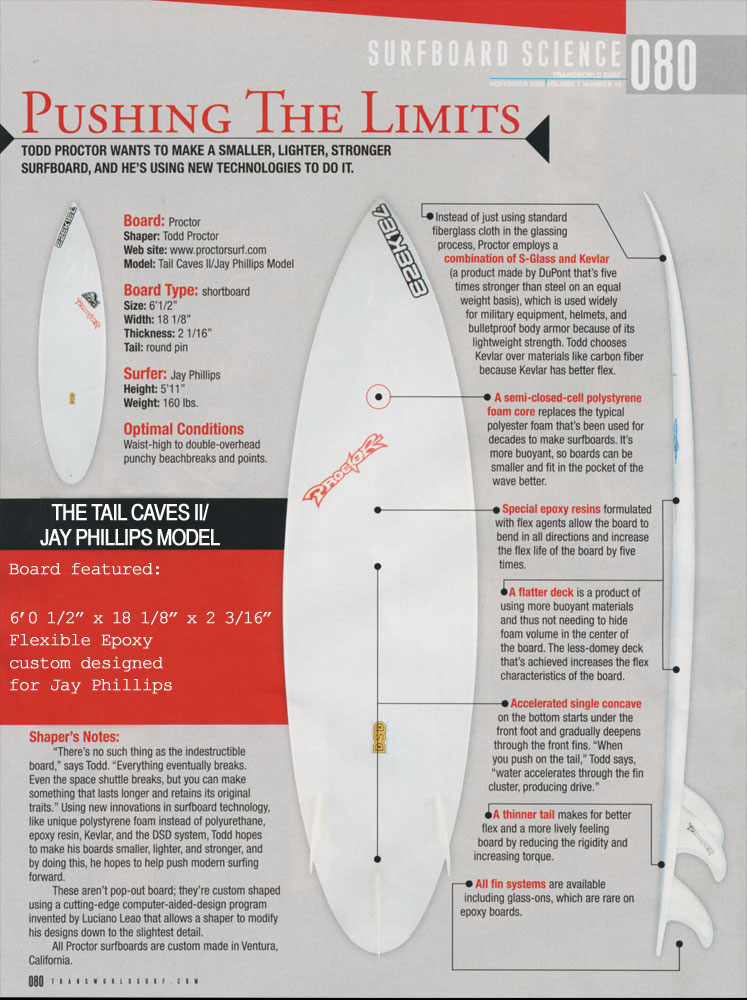

Instead of just using standard fiberglass cloth in the glassing process, Proctor employs a combination of S-Glass and Kevlar (a product made by DuPont that’s five times stronger than steel on an equal weight basis), which is used widely for military equipment, helmets, and bulletproof body armor because of its lightweight strength. Todd chooses Kevlar over materials like carbon fiber because Kevlar has better flex. A semi-closed-cell polystyrene foam core replaces the typical polyester foam that’s been used for decades to make surfboards. It’s more buoyant, so boards can be smaller and fit in the pocket of the wave better. Special epoxy resins formulated with flex agents allow the board to bend in all directions and increase the flex life of the board by five times. A flatter deck is a product of using more buyant materials and thus not needing to hide foam volume in the center of the board. The less-domey deck that’s achieved increases the flex characteristics of the board. Accelerated single concave on the bottom starts under the front foot and gradually deepens through the front fins. “When you push on the tail,” Todd says, “water accelerates through the fin cluster, producing drive.” A thinner tail makes for better flex and a more lively feeling board by reducing the rigidity and increasing torque. All fin systems are available including glass-ons, which are rare on epoxy boards.Shaper’s Notes:

“Theres no such thing as the indestructible board,” says Todd. “Everything eventually breaks. Even the space shuttle breaks, but you can make something that lasts longer and retains its original traits.” Using new innovations in surfboard technology, like unique polystyrene foam instead of polyurethane, epoxy resin, Kevlar, and the DSD system, Todd hopes to make his boards smaller, lighter, and stronger, and by doing this, he hopes to help push modern surfing forward. These aren’t pop-out boards; they’re custom shaped using a cutting edge computer-aided-design program invented by Luciano Leao that allows a shaper to modify his designs dow to the slightest detail.