TOP STORY

Good vibes, great boards: Todd Proctor shares the joy of surfing one board at a time

by Nancy D. Lackey Shaffer Sep 7, 2023

The construction of the modern surfboard is straightforward: a foam core covered with fiberglass cloth, a layer of polyester or epoxy resin, and some fins. For this deceptively simple design, however, the devil is in the details. Width, length and thickness impact its performance, as do tail shape, curvature, bottom contour, the number of fins and how they’re arranged. Small changes in any of these aspects can have enormous impacts in how a board handles in the water. And of course, the needs of every surfer are different.

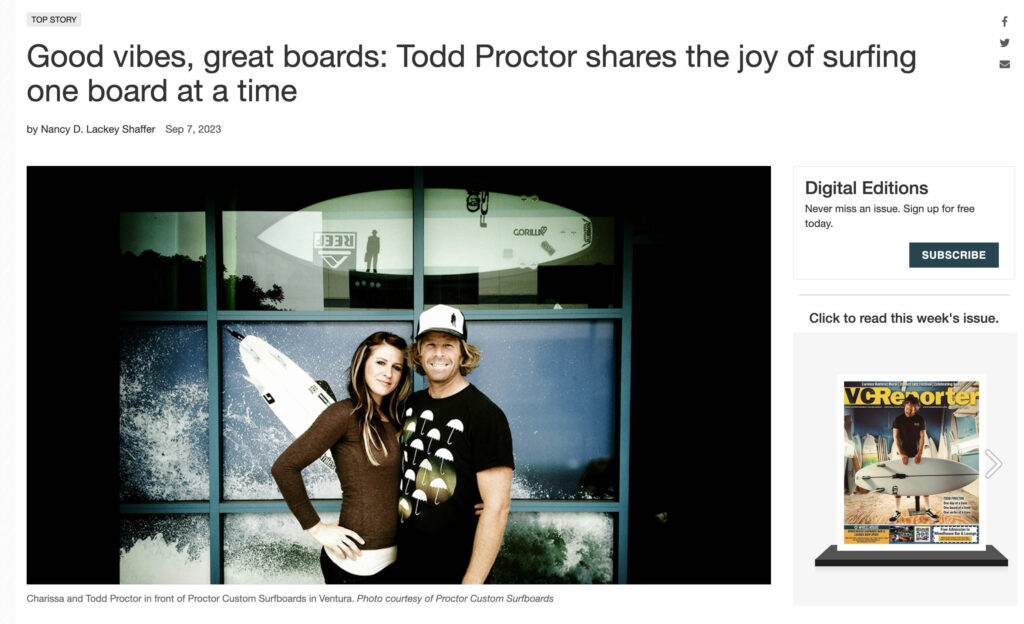

Surfboards lie at the nexus of art, science and craftsmanship, and pulling all of these threads together is the surfboard shaper. And among this group of revered artisans, Todd Proctor looms large. For more than 20 years, Proctor Custom Surfboards has been crafting some of the finest available, each carefully calibrated to their owners. The father-son duo of Peter and Kepa Mendia, Nick Rozsa and Allen Sarlo are among the famous names who have proudly ridden the waves on a Proctor board. But Proctor’s been shaping since he was 18 . . . and surfing even longer. In and out of the water, Proctor has a deep connection to surfing’s sport and culture.

“A taste of heaven”

Like many, Proctor started surfing at an early age. Unlike many, however, he was nowhere near the ocean and about as far from the anti-establishment, hippie-ish surfer stereotype that was prevalent in the 1970s and 1980s.

“I grew up in Los Angeles, the son of a cop,” he explained. “I came from the exact opposite mold of the typical surfer.”

But he did have a neighbor, a few years older, that treated him a bit like a kid brother and let him pal around with him and his friends. One day, this friend took a 12-year-old Proctor up to Malibu Point. He remembers it like it was yesterday.

“Surfing is the best thing that’s ever happened to me!” Proctor recalled thinking.

The grom became a regular passenger on those surf trips, and found himself up in Rincon one winter. He described it as “if someone gave you a taste of heaven . . . that’s what got me in love with Ventura.”

Proctor’s father, LAPD Capt. Vance Proctor, had some concerns about his son’s new hobby — he’d busted more than a few beach bums dealing drugs. But he came around, and Proctor described his father as “really encouraging, really supportive.”

Proctor Surfboards continues to honor the beloved father, police captain and detective, who passed away in 2005 — every board sports a silhouette of a man in a detective suit and hat: Vance Proctor memorialized in logo form.

“Go on your own journey”

Over time, Proctor’s passion and skill grew. He sought out custom shapers to help him add to a growing “quiver” of boards. A deft hand himself with woodworking and shop tools, Proctor was fascinated by what the shapers were doing — taking a foam “blank” (the starting point for every surfboard) and carving it into something seaworthy and ridable. But when he tried to ask them about their process, he hit a bit of a wall.

“They tried to discourage me,” Proctor said. “‘It is the dirtiest job. You don’t make any money. You’re unappreciated.’ So no one shared knowledge.”

Disappointed but undaunted, Proctor did the next best thing: “I went down to the public library and got a book . . . I studied the book like I was taking a college course.”

Proctor was 18 at the time, and in those days, blanks weren’t something a person could just buy in a retail shop. Luckily, Glen Kennedy, founder of Kennedy Surf Shop in Woodland Hills (who passed away in 2019), decided to help the would-be shaper out. He provided Proctor with four blanks . . . and gave him a piece of advice that he’s followed ever since: “Don’t listen to me and don’t listen to anybody else, either . . . you go on your own journey.”

Proctor’s shaping journey started in the Reseda woodshed of his maternal grandfather, an Italian immigrant and World War II veteran who offered up the space so long as his grandson kept it tidy and cleaned up after himself.

“I rigged out the whole woodshed based on that book,” Proctor affirmed. A friend that was a welder even made him a steel rack, which he uses to this day. Following the guidelines set out in that book, as well as what knowledge he had as a skilled woodworker and a die-hard surfer, he shaped all the blanks — one for himself, the others for friends.

“This is what you’re meant to do”

Shaped foam still needs to be covered in fiberglass and resin to become a strong, waterproof, usable surfboard. So Proctor brought his hand-shaped blanks to Casey McCrystal, one of Southern California’s top surfboard shapers and glassers, to his shop in Oxnard (McCrystal Surfboards has since moved to Ventura).

“That was the first time I saw the inside of a facility making boards,” Proctor added.

The “shop kid” that did the intake got to chatting with Proctor, asking if he’d shaped those boards himself (he had) and if this was the first time he’d shaped (also yes). Proctor was grateful the shop was willing to glass his blanks — he feared that his obviously amateurish work might be too humble for such a high-class outfit.

Proctor got in the car to head home, but didn’t get far before he was stopped by none other than Casey McCrystal himself.

“He runs out in front of my car, and says, ‘hey! wait!’”

Proctor’s “amateurish” blanks had impressed the renowned shaper with their skill and finesse. Maybe Proctor didn’t know everything there was to know about the creation of surfboards . . . but the kid clearly had a gift.

McCrystal hired Proctor on the spot, saying, “You need to become a shaper . . . This is what you’re meant to do with your life.”

He honed his surfboard manufacturing skills at McCrystal, and later went on to work at other manufacturers, including Lost Surfboards in San Clemente, where he was one of the top designers and had his own shaping room.

“That was where I worked with the pros,” Proctor said. “I threw myself into that and really learned about high production.”

There were also a few breaks to travel and surf, which became an education in itself. A year in Australia, a season in South Africa, trips to Hawaii and South America.

“For about a 5-10 year period, I just went on the full ‘I’m going to surf every wave’ thing,” Proctor said. “You find this tribe that is worldwide . . . you’ve immersed yourself in a community.”

Surfboards for everybody

Something else happened to Proctor as he rose through the ranks of shaping and design: He saw the drawbacks of large-scale surfboard manufacturing.

“I started to realize most of the companies were kind of elitist,” he explained. “The athletes were super well taken care of . . . that was awesome . . . but it became very one dimensional.”

“Unrelatable” is one of the words that came to mind when Proctor talked about his time working at the big surfboard companies. Top-tier athletes got the manufacturers’ time, attention and best work. The average surfer got mass-produced, carbon-copy options.

“My heart went to the experience of the normal people and how surfing blesses their lives,” Proctor said. “I wanted to raise the frequency of

the planet.”

In short: Proctor wanted to use his gifts to bring the joy and blessing of surfing — which had been so transformative for himself — to anyone who wanted to embrace it, regardless of their abilities.

In 2001, Proctor decided it was time to branch out on his own and live the ethos that had been developing in his soul since his first ride at Malibu Point as a pre-teen. He had a vision for his business, and knew that he wanted it to be in Ventura.

“It’s always come back to that time when I was 12 and I surfed Rincon,” he said. “This is a very special place. This is where I’ve always wanted to be.”

He found a space in Ventura’s industrial zone, on Goodyear Avenue off of Market Street. Proctor Custom Surfboards has been there ever since.

“Miraculously, year after year, I’m still here,” he said.

Optimized experience

That’s due in no small part to wife Charissa, who is an integral part of Proctor Surfboards, handling the business, website, IT, customer service and initial consultations with clients. She is also responsible for mixing all colors that are used for custom resin art, tints, digital laminates and airbrushes — practically a full-time job all by itself.

Proctor does employ a skilled crew to help him handle his 100% custom business. Nevertheless, he’s involved in every aspect of the business.

“He is in and out of all the rooms in our factory daily overseeing the crew and every phase of the fabrication process,” Charissa noted. “He takes an active interest in all parts of the process, and still jumps in on occasion hands-on in the [lamination] room and sanding room to continue honing technique.”

Being independently owned has allowed Proctor to keep up with innovative materials and techniques, too. For example, he worked with a Ventura-based company to formulate an epoxy foam specially developed for surfboards, employs an epoxy resin with a cleaner refining process, and uses hybrid fabrics and composites for optimal strength, durability and flex.

“One day at a time, one surfer at a time, one board at a time” is the company motto, and it lives up to that name. Where “most surf shops have a size and weight chart,” Charissa explained that Proctor looks at everything: size, weight, center of gravity, experience, life circumstances, where the client surfs, what kinds of waves they ride, body mechanics, hydrodynamics and more. “We also keep detailed records of every board.”

Proctor’s aim is to allow clients to have “the best time they can possibly have in the water,” with a board that will last a lifetime — rather than mass-producing hundreds of the same board that flood the market and end up in the trash after a season.

“I build to the demand,” he clarified.

For the people and the planet

Proctor, ultimately, thinks surfing is good for both people and the environment, which he sees as fully linked.

“Human mental and physical health are part of the planetary ecosystem,” he said. “I think they should exist together in harmony.”

One of his aims is to create surfboards in the most environmentally way possible. Thus, he uses “the best materials so they last the longest, and make it custom and personalized so [customers]’ll hold onto it. They don’t end up in the landfill, ever. It’s something almost sacred.”

Social justice is just as important to Proctor, who has tried to foster a very family-oriented workplace (particularly since the birth of daughter Indie, now 5). He’s also tried to give his employees the cleanest, healthiest environment in which to work, employing state-of-the-art technology to filter fumes from the various chemicals used in the surfboard manufacturing process.

“My CFM is eight times what is usually required by the county,” Proctor said proudly of his air-scrubbing system.

And for his customers, he tries to deliver a board that will fill them with the same joy and wonder he has always felt. It’s what led Proctor down his own life’s path, and he sees his work as one way of giving some of those good vibes back to the larger community.

“Todd’s taking 30 years of experience with what works to help you on your surfing journey,” Charissa said. “You can’t automate that.”

“[Surfing] let me focus all my energies into something so life giving,” Proctor summed up. “I want to give that to others.”

Proctor Custom Surfboards

1920 Goodyear Ave., Suite A, Ventura

805-658-7659

More about Todd Proctor, his journey and his process and can be found at: