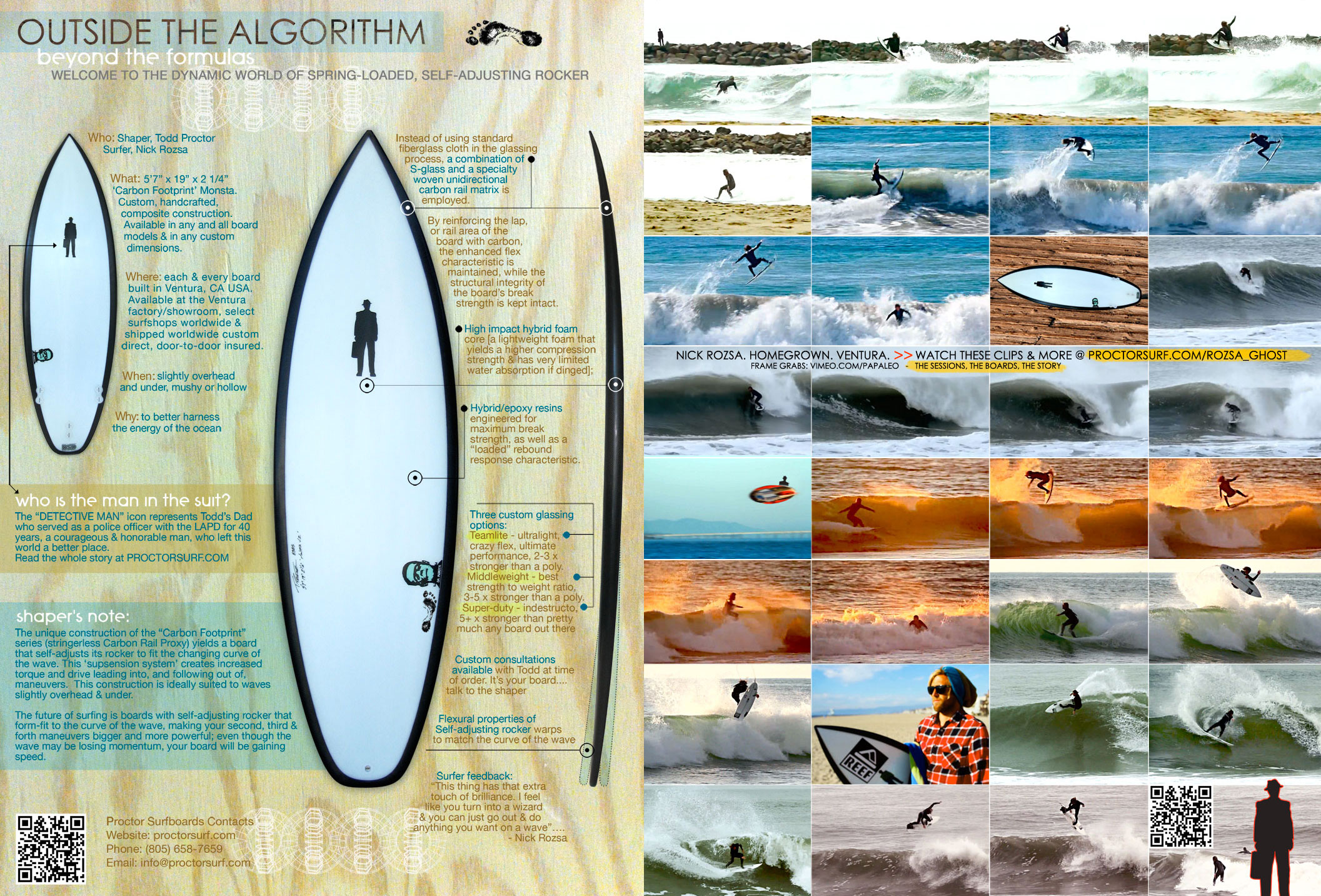

shaper breakdown:

The carbon used to reinforce the rail lap matrix is woven in a specific pattern/gauge ideally suite for maximum performance and strength. The carbon reinforced rails in combination with the stringerless blank provide an enhanced flex characteristic that is very noticeable for surfers of all skill levels.

–Todd

A stringerless board exhibits incredible flex, torque u0026amp; recoil through turns. However, with no center stringer, the board’s break strength (also called ‘tensile strength’) is significantly diminished. By reinforcing the lap, or rail area of the board with carbon, the enhanced flex characteristic is maintained, while the structural integrity of the board’s break strength is kept intact. This is because boards break by creasing from the rail u0026amp; buckling inwards, not from the center out. Case-in-point: How many times have you seen a buckled board creased from the rail, across the deck and stopping at the stringer? This is where the placement of a high-grade composite like carbon is strategic in reinforcing the board’s rail strength… without constricting the increased flex pattern.

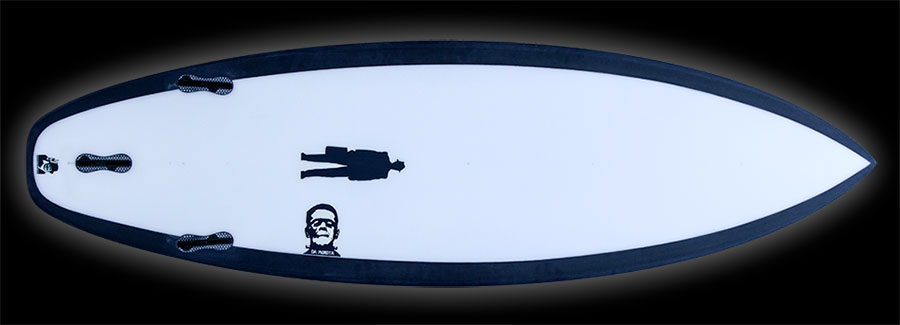

The Carbon Rail stringerless construction yields an increased flex pattern that gives more speed through the flats and a rocker that warps into the steep parts of the wave face; forming into the shape of the wave creating a slingshot effect both into and out of maneuvers…..IT’S ALIVE!! It’s also 3-5+ times stronger than a poly.

1 >> proxy epoxy composite :::

High Impact Hybrid Foam Core // [a lightweight (lighter than teamlite Proxy epoxy) foam that yields a higher compression strength and has very limited water absorption if dinged]

2 >> S-Glass :::

S-glass is the highest-grade fiberglass available and will make any board significantly stronger. It is available in 4oz. and 6oz.

3 >> Hybrid/Epoxy resins :::

engineered for maximum break strength, as well as a “loaded” rebound response characteristic, we use a unique blend of resins that yields an ultra-white uv stabilized aesthetic

RIDICULITE – fright-light, crazy flex, ultimate performance, about twice as strong as a poly

TEAMLITE – ultralight, crazy flex, ultimate performance, 2-3 x stronger than a poly

MIDDLEWEIGHT – best strength to weight ratio, 3-5+ x stronger than a poly

SUPER-DUTY – indestructo, 5+ x stronger than pretty much any board out there

Care for your Proxy surfboard simply consists of keeping it watertight; ie. If you do get a ding, just allow it to dry out and then repair it with epoxy resin specifically made for surfboard repair; or if you take it to a shop to repair, make sure you let them know to use epoxy resin. That’s it. Also, use the same common sense care you would for a polyester board, just don’t leave it laying in the sun. If you have any questions, let us know.

Nick Rozsa demonstrates the flexural properties of his 5’7 Monsta … and leaves a Carbon Rail footprint upon the earth

[instagram-feed type=user user=proctor_surfboards includewords=”#carbonfootprintsurfboard” nummobile=3]